CELEBRATING OUR FIFTY-FOUR YEARS! 1968 - 2022 435 SOUTH COUNTY LINE ROAD • FRANKLIN PARK, IL 60131-1092 • 1-800-BJ BOXES

Services

Our Goal - Customer Satisfaction

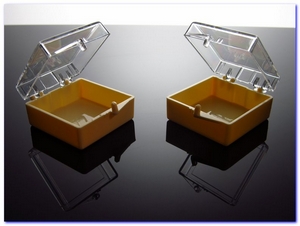

A "reusable" and "recyclable" plastic box will protect and enhance your products and give the consumer a "reusable container" once the product has been used, which is something that a "blister" or "clam shell" generally will not do.

What we offer

In today's global marketplace your products need to attract potential customers with quality, at a competitive price, the right package, which especially now means a "reusable" rigid plastic box. A better package can increase your sales, reduce your packaging costs, reduce product damage, has direct customer appeal and a new product look.

Relentless Effort = "Results"

Create your own package with a variety of stock colors, custom imprinting, including the "sharpness" of pad printing which enables the box to be printed with a UPC Bar Code.

Customizing our boxes is easy with our imprinting and decorating services, including hot stamping and pad printing. To determine the best method of imprinting for your project, we will work closely with you for your customized box. We can create the package to successfully market your product.

Your die cut information cards can be extended thru the back of the box between the "hinges" enabling your products to be displayed on a rack while eliminating the added cost of "blister" packaging.

Color Matching

The right color can be very critical. Having the right color

part is just as important to B.J. Plastic Molding, as it is to many of our customers.

Color intelligence and technology-driven solutions underscore B.J. Plastic's commitment

to our customers. On-site color and process consultation services provide assistance to companies

to assure complete customer color satisfaction. We make sure the color of your parts match within

each production run and from run to run.

The right color can be very critical. Having the right color

part is just as important to B.J. Plastic Molding, as it is to many of our customers.

Color intelligence and technology-driven solutions underscore B.J. Plastic's commitment

to our customers. On-site color and process consultation services provide assistance to companies

to assure complete customer color satisfaction. We make sure the color of your parts match within

each production run and from run to run.

Hot Stamping

Hot stamping is a dry printing method in which a heated die and foil are used to apply graphics to a surface. Foil is the ink of a hot stamping operation. It is made up of a carrier with a series of coatings including color to be transferred. Foil stamping is environmentally friendly due to it being a dry process. It does not use solvents or inks and does not create any harmful vapors.

Hot stamping is a dry printing method in which a heated die and foil are used to apply graphics to a surface. Foil is the ink of a hot stamping operation. It is made up of a carrier with a series of coatings including color to be transferred. Foil stamping is environmentally friendly due to it being a dry process. It does not use solvents or inks and does not create any harmful vapors.

Insert Molding

Insert molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. Metal inserts can also be injection molded into the work piece. For parts made in large quantities, inserts are placed automatically into the mold.

Insert molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. Metal inserts can also be injection molded into the work piece. For parts made in large quantities, inserts are placed automatically into the mold.

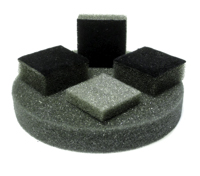

Thermoformed Inserts

Thermoformed Inserts are designed to help organize and transport damage-free products

to consumers. Foam is a perfect packaging solution to keep products in place with an appealing and secure display structure.

Thermoformed Inserts are designed to help organize and transport damage-free products

to consumers. Foam is a perfect packaging solution to keep products in place with an appealing and secure display structure.

Pad Printing

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an offset process that involves an image being transferred from the cliché via a silicone pad onto a substrate. Pad printing is used for printing on many products including medical, automotive, promotional, apparel, and electronic objects.

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an offset process that involves an image being transferred from the cliché via a silicone pad onto a substrate. Pad printing is used for printing on many products including medical, automotive, promotional, apparel, and electronic objects.

Package Development

B.J. Plastic Molding leads your entire

package project from beginning to end. Representatives from sales,

engineering, quality assurance, materials purchasing, and

manufacturing form a team that will work with you throughout your

project.

B.J. Plastic Molding leads your entire

package project from beginning to end. Representatives from sales,

engineering, quality assurance, materials purchasing, and

manufacturing form a team that will work with you throughout your

project.

Quality Assurance - As an ISO 9001-2015 certified supplier and manufacturer, we prevent potential problems by using such tools as Advanced Quality Planning (AQP), and Design Failure Mode Effects Analysis (DFMEA). We operate at or near zero ppm defects.